The resilient seat gate valves provide the most reliable solution for networks. They guarantee perfect watertightness, without leakages and smooth flow with minimum losses. They are designed so as to avoid corrosion risks. No bolts and nuts are found externally.

The construction materials are of high quality and endurance that assure long life valve operation. The valve can be dismantled without being removed from the pipeline. The valves are internally and externally coated by epoxy powder, electrostatically applied, thickness 200μm (extra thickness upon request).

The operation of the valve is achieved by a handwheel and with suitable spindle extensions in case of underground installation or deep manholes. The valve can be accompanied by a gearbox which is mounted on a special adjustment head.

The gate valves are manufactured according to the international standards ISO, DIN, EN. They are tested thoroughly at each stage of production. The tests are executed according to DIN 50049 3.1B / EN 10204-2004 in the GEMAK test laboratories of latest technology.

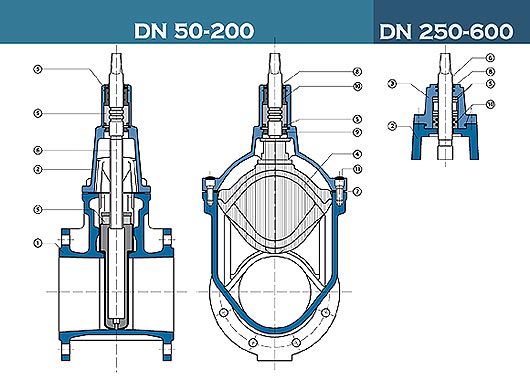

Sizes DN50 up to DN600 in F4 (short pattern) & F5 (long pattern)

Working pressure ΡΝ10atm- PN16 from DN50 up to DN600 , PN25atm from DN50 up to DN250

Working Temperature -10oC up to +80oC

| DESCRIPTIONMATERIAL | ||

|---|---|---|

| 1 | BODY |

Ductile Iron A. GGG40 DIN1963/ EN 1563 B. GGG50 DIN1963/ EN1563 (upon request) |

| 2 | COVER | |

| 3 | CAP | |

| 4 | SEALING BODY | Ductile Iron A. GGG 40 DIN 1693 B. GGG 50 DIN1693 (upon request) vulcanised with ΕΡDM |

| 5 | BEARINGS | Copper Ms 58 DIN 17660 or RG5 or TEFLON |

| 6 | STEM | Stainless Steel Χ20Cr13 DIN 17440 |

| 7 | SEALING FLANGE | EPDM |

| 8 | SEALING RING | EPDM/NBR |

| 9 | STEM SEALING RING | EPDM/ NBR |

| 10 | O-RING | EPDM/ NBR |

| 11 | BOLTS | Steel DIN912, galvanized or ΙΝΟΧ upon request |

The valve is also available with position indicator upon request