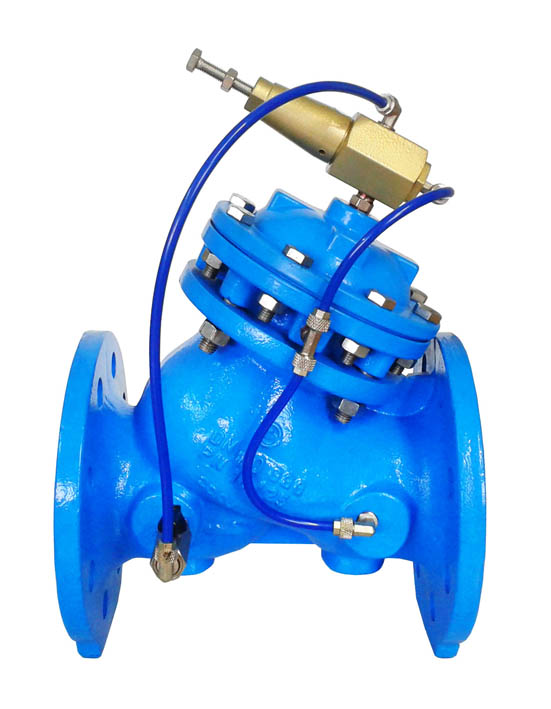

GEMAK created the design of this series of valve AS-A in order to eliminate the problems, found to the irrigation-water supply and pumping networks. AS-A series valves are hydraulically operated by means of a diaphragm which is located to the interior of the valve. Their regulation does not need any special knowledge. By mounting various pilots or three-way electromagnetic valves on their body, a large range of applications is achieved and all demands for regular and soft operation as well as for total protection of the waterworks are covered. Such as:

By using additional equipment we can regulate the opening and closing speed of the diaphragm from 0.2 up to 180sec creating ideal conditions for the safety and protection of pump stations and water networks. The valve series AS-A is available in two types: 1) Type Υ double chamber and 2) Angle shaped type with single and double chamber

The valves of the double chamber give the ability for multiple applications and smooth closing and operating (T=0.2sec-180sec) and therefore the creation of even a small pressure surge caused by the valve itself, is avoided. The valves of the single chamber have a limited margin of applications but they give the same safety and operation conditions as those of the double chamber, when they are used for the regulation of pressure and the immediate relief of pressure.

Using hydraulic diaphragmatic valve series AS-A we achieve:

Diaphragmatic valves can function, either electrically on ON-OFF conditions or hydraulically with capability of proportional control operation, (opening closing from 0,2sec to 180sec).

Diaphragmatic valves series AS-A with double chamber are constructed in two different configurations:

1. type Υ , series AS-A/Y

2. angle configurationM series AS-A/T

Due to their special design, maximum flow with minimum losses is achieved. The material used for the body's construction is ductile iron of spheroidal graphite GGG40/50 DIN 1693/ EN 1563. The main part of the internal mechanism, i sthe diaphragmatic actuator. The actuator's diaphragm is a membrane, made of nyln reinforced neoprene of high resistance and flexibility. This, divides the chamber, which is bethween the actuator's base and the cover, into two parts which are fluctuated according to the accepted rate of pressure. The mebrane is tighth to the end, with stainless steel bolts and held by two discs, made of copper DIN 1705 CuSn12 or steel GS45.The sealing disc is copper DIN1705 or steel GS45 with an elastic gasket made of EPDM for absolute water tightness and long life time. Between the actuator's base and the sealing disc, a stainless steel AISI 316 spring is placed which presses the sealing disc tighly. By connecting different pilots and electromagnetic valves we can acheive various application s for the smooth operation of the network.

The difference in pressure which appears in te two chambers of the actuator, through the pilot and the pressure inlet, is responsible for tha axial movement of he mechanism and the automatic operation. The valve will open when the inlet pressure exceeds the outlet forces of hte upper diaphragm and sping. In the case of equality between the outlet pressure and the regulated pressure, the valve tends to close, due to the pressure caused by the spirng. This operates as as check valve and closes totally when the inlet pressure is lower than the regulated outlet pressure.

Sizes:

Valve configuration 'Υ': DN50 - DN450 (bigger sizes only uppon request)

Valve angle configuration: DN50 - DN100

Working Pressure : 10 bar -16 bar -25bar (for high pressures the piston type valve is recommeded)

Working Temperature : -10oC up to 80oC

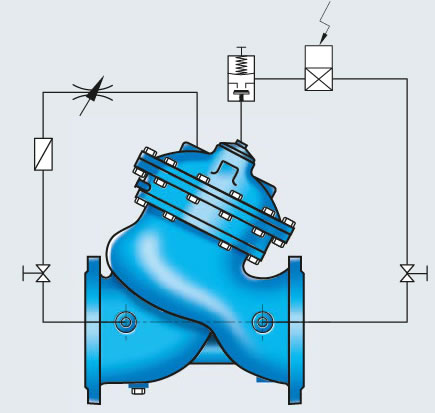

Diaphragmatic double chamber valve. The valve closes and opens smoothly by accepting electic signals from a 3-way electromagnetic valve.

more

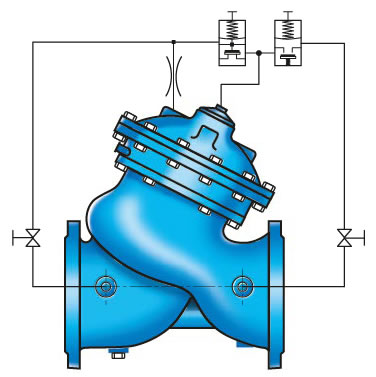

Diaphragmatic valve AS-A/Y-10-10 is double chamber, flanged, with two electromagnetic control valves.

more

Pressure reducing valve. The valve reduces the pressure to a constant downstream pressure regardless the changes of the upstream pressure and /or flow.

more

The valve reduces the pressure to a constant downstream pressure regardless the changes of the upstream pressure and /or flow. It is ideal for fire extinguishing networks, buildings and blind pipelines.

more

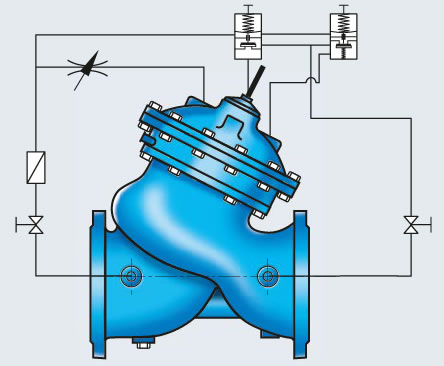

Diaphragamtic double chamber pressure reducing valve controlled by a 2-way solenoid valve

more

Ideal in cases where the pipeline is separated towards different directions before the point where the valve is installed. The valve maintains a constant upstream pressure while it reduces the upstream pressure to a lower downstream pressure.

more

Anti hammer shock, surge preventing valve, diaphragmatic type with double chamber, Y configuration. The valve opens on negative pressure wave and prevents the pressure from exceeding the nominal pressure of the network

more

Electrical surge protection valve, which detects and reliefs negative surge waves and also protects from overpressure

more

Diaphragmatic double chamber pressure relief valve. It is actuated when there is overpressure in the the netowork. Types available: AS-A/Y-30 ‘Y’ configuration , ΑS-A/T-30 angle shaped, AS-R/Y-30 threaded connections for pressures exceeding 25atm piston type valve AS-P/Y-30 is recommended.

more

Prevents pressure surges caused by the starting and closing of the pump. The valve opens and closes while the pump is on and prevents back flow if there is a power failure. In combination with the surge control valve type AS-A/Y-30 or AS-A/Y-35, the valve provides smooth operation conditions regardless the increases or decreases of the flow...

more

The valve is used for the filling up of reservoirs/tanks as it maintains a pre-set upper level in the reservoir/tank

more

Two Level Control Diaphragmatic Valve, with control mechanism 50-61

more

Protects pumps and pump stations Valve Series AS-A/Y-70 has a pilot to control the water velocity and to stabilize the flow of the pump and also reduces the absorbed power. In combination with the hydraulic inverter it provides complete protection of the pump station. it can:...

more

Pressure relief valve for sewage networks

more